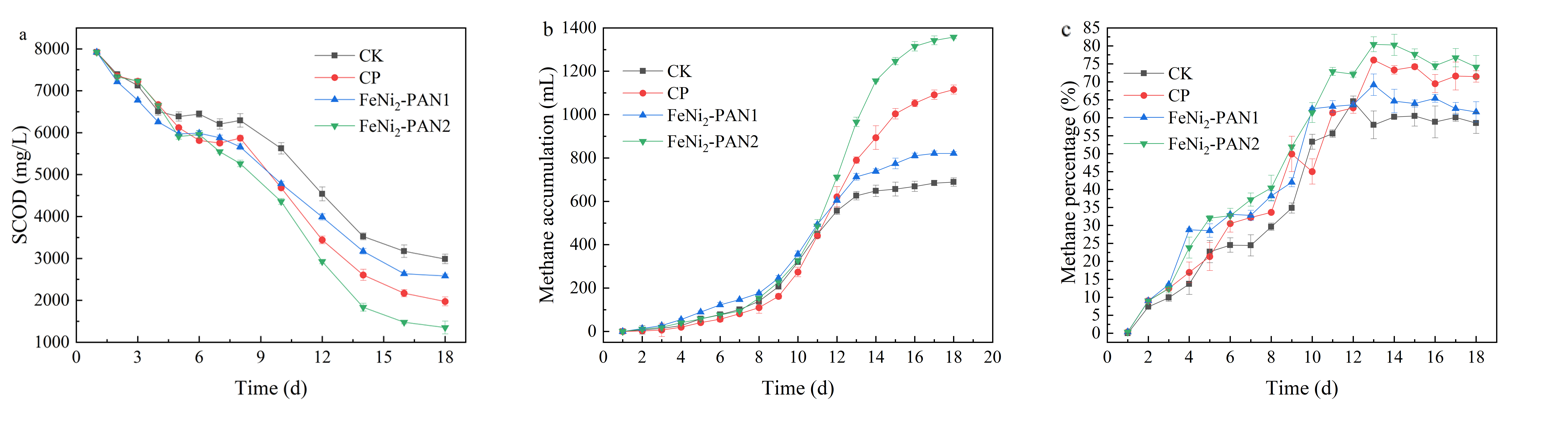

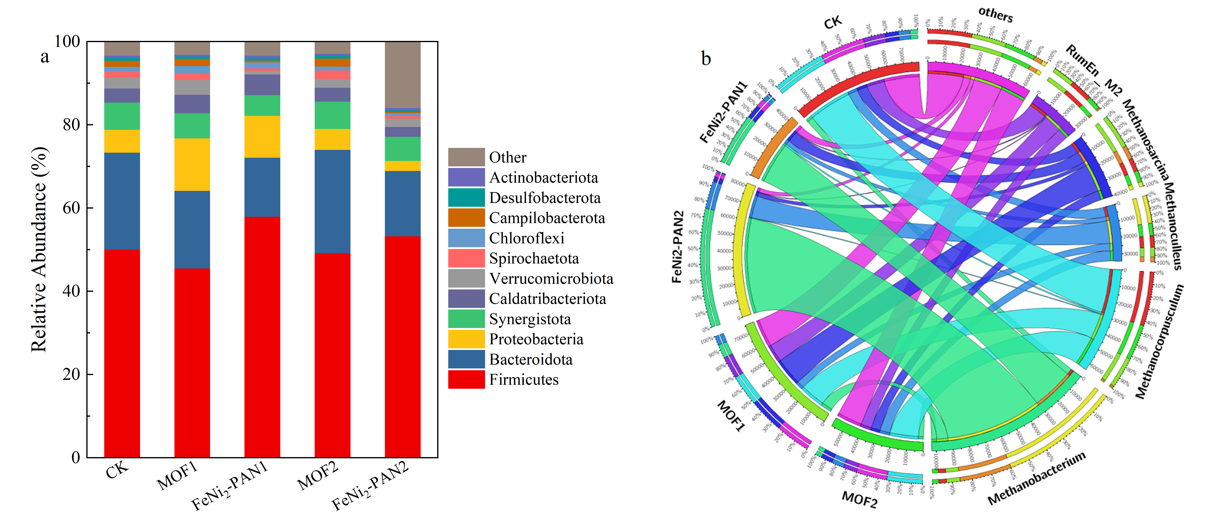

Stainless steel mesh, as the common cathode of microbial electrolytic cell-assisted anaerobic digestion (MEC-AD), has the disadvantages of low specific surface area, poor biocompatibility and low catalytic activity, which limits the production of methane. Metal-organic frameworks (MOFs) have attracted much attention due to their adjustable pores and specific catalytic properties. However, little attention was paid to the combination of MOF and stainless-steel mesh to improve the performance of MEC-AD cathode. In this study, we combined stainless steel mesh with bimetallic MOF catalyst (Fe/Ni-NH2BDC) to prepare a composite cathode, and verified its promoting effect on AD of swine wastewater. The experimental results showed that the reactor with the carbonized MOF composite cathode (FeNi2-PAN2) achieved the highest soluble chemical oxygen demand removal rate of 82.92% and a maximum cumulative methane yield of 213.47 mL CH4/g COD under an applied voltage of 0.8 V, which were 33.14% and 57.56% higher than those of an anaerobic digestion (AD) control reactor, respectively, and higher than those of a carbon paper (CP) cathode reactor. The enrichment of Methanobacterium and Methanoculleus on the surface of FeNi2-PAN2 cathode surface indicated that FeNi2-PAN2 cathode enhanced hydrogenotrophic methanogenesis and improved the stability of AD.

Fig. 1. (a) SCOD removal. (b) Accumulated methane production. (c) Methane percentage produced by the different reactors.

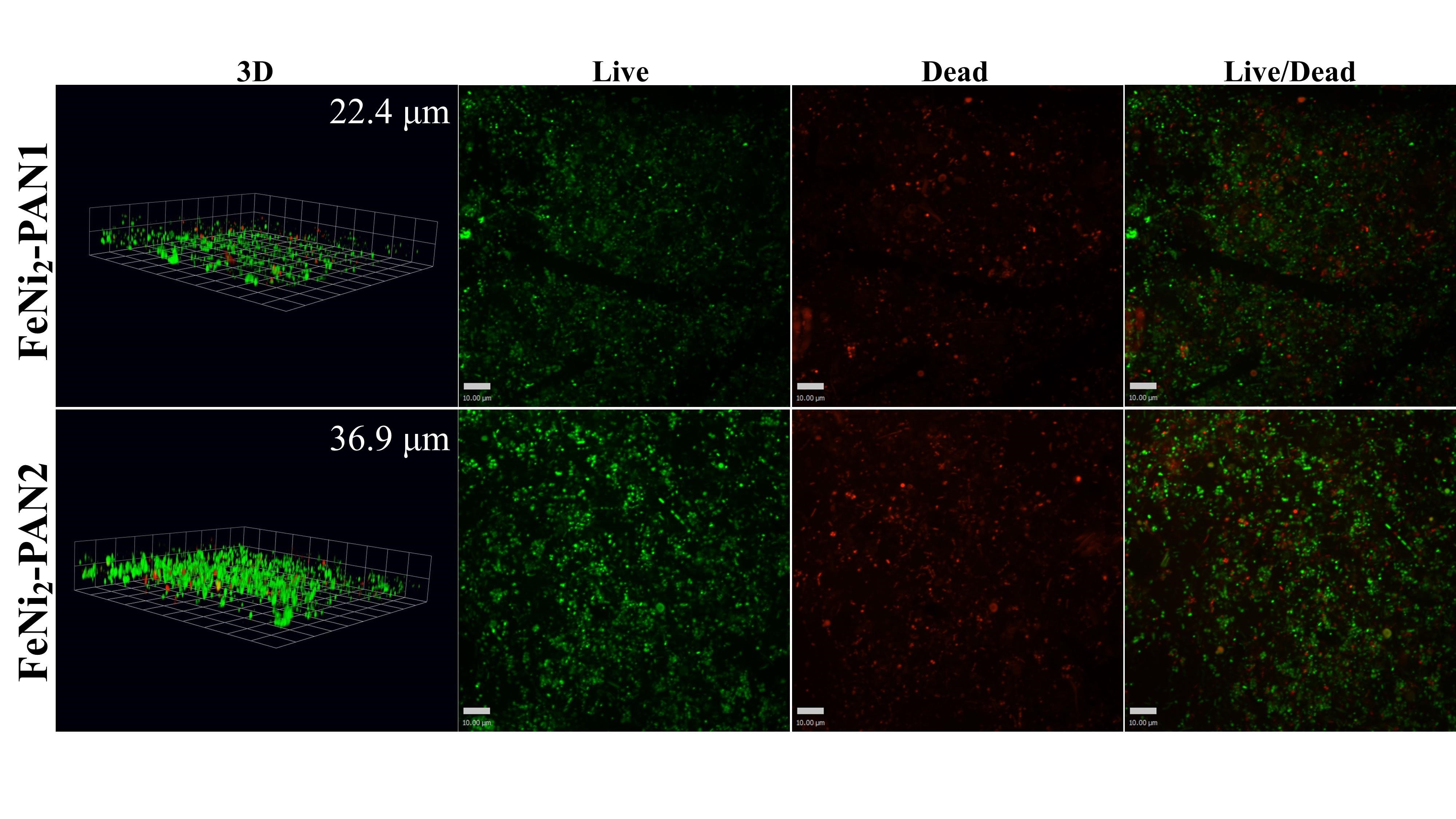

Fig. 2. CLSM characterization of biofilms with FeNi2-PAN1 and FeNi2-PAN2 cathodes.

Fig. 3. (a) Bacterial community structure at the phylum. (b) Archaeal community structure at the Circos diagram of relationship between samples and species at the genus level.

Read more: https://doi.org/ 10.1016/j.jclepro.2022.134773