Carbon nanomaterials including graphene, carbon nanotubes and carbon quantum dots are widely used as the photo-thermal conversion agents for preparing shape memory materials due to their excellent light absorption and thermal conductivity. However, the preparation of these carbon materials relies on non-renewable fossil resources with complicated/harsh synthesis methods. With the emerging energy shortage, it is of great importance to prepare photo-thermal responsive shape memory materials with the introduction of carbon nanomaterials derived from renewable biomass wastes. However, only a few researchers have focused on the thermal or photo-thermal responsive shape memory materials with deep-processed biomass monomers or compounds, such as epoxy soybean oil, vanillin, lignin, larch bark extracts, which inevitably increases preparation complexity and cost expensiveness.

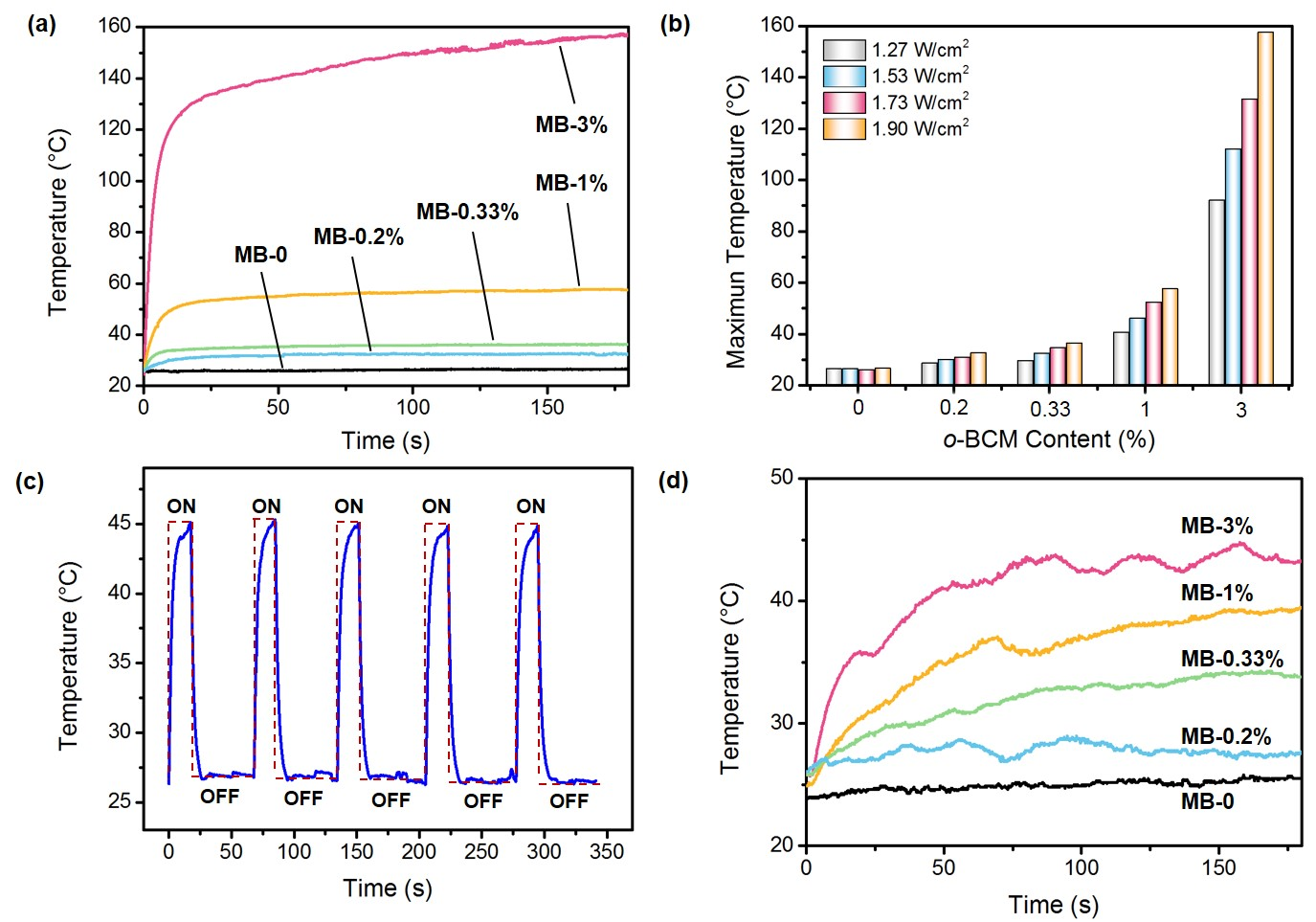

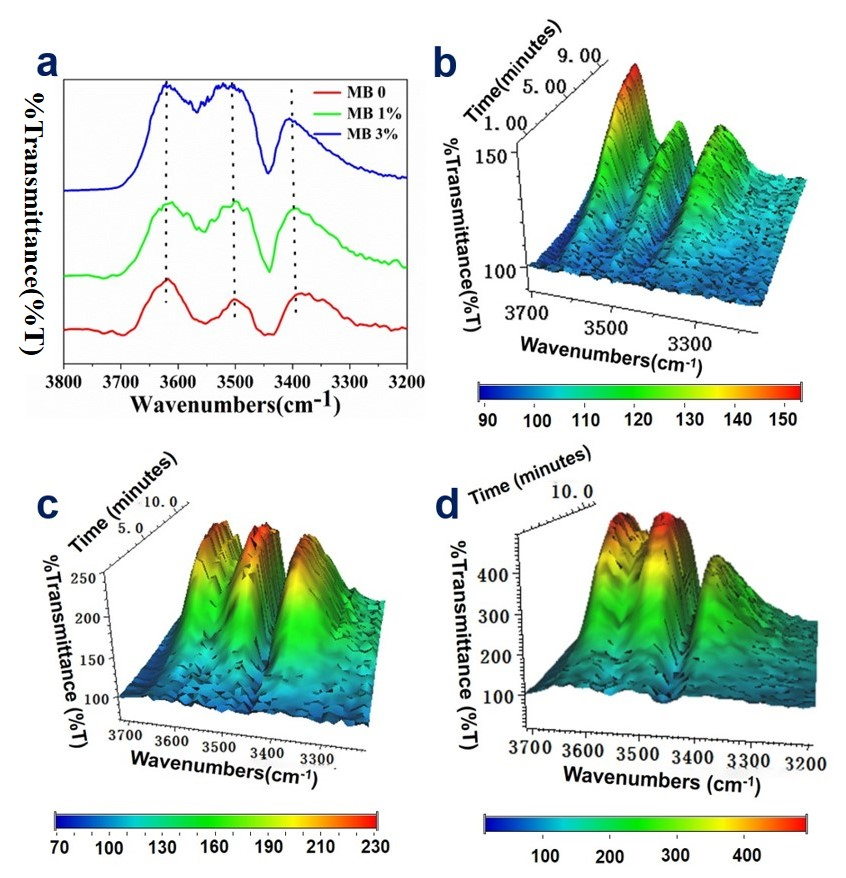

Recently, the advanced agricultural materials team of Jiangsu Academy of Agricultural Sciences in China, published an online research article entitled “Photo-responsive shape memory polymer composites enabled by doping with biomass-derived carbon nanomaterials” in Nano Research (IF=8.897). The team demonstrated the fabrication of a novel light-triggered shape memory composite by incorporating biomass-derived carbon nanomaterials from crushed farmland waste of corn straws without deep purification and processing. These carbon nanomaterials not only have stable dispersion in polymers, but also can endow the polymers with excellent and stable thermal and photo-thermal responsive properties in biological friendly environment. The thermal responsive properties can be induced below the temperature of 20 °C which is quite safe to normal biological body, and the photo-thermal responsive shape memory behaviors can be triggered with the addition of only 0.2 wt% carbon nanomaterials (Figure 1a, b) with excellent stability (Figure 1c). The photo-thermal responsive properties can also be induced with sunlight (Figure 1d). With the introduction of biomass-derived carbon nanomaterials, the mechanical properties of the composites are also enhanced with the formation of hydrogen bonding between the carbon nanomaterials and the polymers. Notably, the doping of 1 wt% carbon nanomaterials endows the polymer with sufficient intramolecular and intermolecular hydrogen bonds that not only exhibit excellent thermal and photo-thermal responsive properties, but also with enough space for the motion of chains (Figure 2). These properties make such composite a promising and safe candidate for shape memory applications, which provide a new avenue in intelligent soft robotics and high-value utilization of agricultural biomass wastes.

Figure 1 (a) The temperature-time curves of the polymers with various contents of carbon nanomaterials exposed to near-infrared laser with the light intensity of 1.90 W/cm2; (b) the equilibrium (maximum) temperature of the polymers as functions of near-infrared light intensity and nanomaterial concentrations; (c) temperature elevation of MB-0.33% (composites with 0.33 wt% biomass-derived carbon nanomaterials) exposed to 3.62 W/cm2 near-infrared laser for five cycles. The near-infrared light is alternatively on for 20 s and off for 40 s; (d) the temperature-time curves of the polymers with various nanomaterial contents exposed to 1 sun irradiation.

Figure 2 (a) The spectra of composites with 0, 1 wt% and 3 wt% biomass-derived carbon nanomaterials in 10 mins in situ Fourier transformation infrared characterization (the samples were heated into 50 °C in 10 mins, and the original transmittance value of the samples were set as 0 point); (b-d) The 3D Fourier transformation infrared spectra of composites with (b) 0, (c) 1 wt% and (d) 3 wt% biomass-derived carbon nanomaterials, respectively.

The first author of the study is Nina Yan, the assistant professor in Institute of Agricultural Facilities and Equipment in Jiangsu Academy of Agricultural Sciences. The corresponding authors are Lei Xu (associate professor in Institute of Agricultural Facilities and Equipment in Jiangsu Academy of Agricultural Sciences), Qingbao Guan (associate professor in Donghua University) and Haitao Li (professor in Jiangsu University). This work was supported by the Jiangsu Agriculture Science and Technology Innovation Fund (CX(19)3085), Jiangsu University acknowledges National Natural Science Foundation of China (Grants 51802126, 52072152) and Jiangsu Province Distinguished Professor Plan.

The article DOI: 10.1007/s12274-021-3674-7