Consumption of animal-based food has been closely related to the nutritional needs of the population. The global output of livestock and poultry, and aquatic products was, respectively, 2365 and 1778 million metric tons in 2018. As a result, a large amount of animal by-products are generated, including feathers, fish scales, blood, bones, skin and viscera, among others. These by-products contain an abundance of protein, fat, carbohydrate, minerals, vitamins as well as other nutrients. Animal livers are important by-products in food processing industry as they account for 2-3% of the body weight of animals. Livers serve as an excellent source of high-quality protein and bioactive enzymes. The need for animal protein resources encourages the search for and use of unconventional supplies. However, animal livers are commonly sold unprocessed at a low price since their unique properties and high-value utilization have not been fully explored. Fully use of animal livers provides an opportunity to utilize existing resources of food protein to the utmost and reduce the environmental pollution from the meat production when these raw materials not properly processed.

Most of biochemical reactions that constitute the metabolism of organisms are catalyzed by active proteins, and the immune response of humans mainly needs proteins. Therefore, the development of protein and its bioactive hydrolysates have gradually become an important strategy to seize the forefront of life science and technology. The increasing world population and the demand of food with high nutritional values are expected to increase the need for more animal-derived protein by the year 2050. However, most animal livers are sold at a low price and used to produce animal feed due to lack of appropriate technology and processing equipment (Pilarczyk et al., 2020). Liver protein hydrolysates have excellent process characteristics (e.g., acid-base and heat resistance, good solubility and water retention, etc.) and nutraceutical value (Bhandari et al., 2020), however their use is limited in food or nutritional supplements due to lack of detailed research. Innovative technologies guarantee effective conversion of animal processing by-products into biologically active protein hydrolysates and procurement of high activity proteases. Therefore, effective utilization and development of value-added products of animal livers as well as realization of their sustainable development is an important topic in the animal food industry.

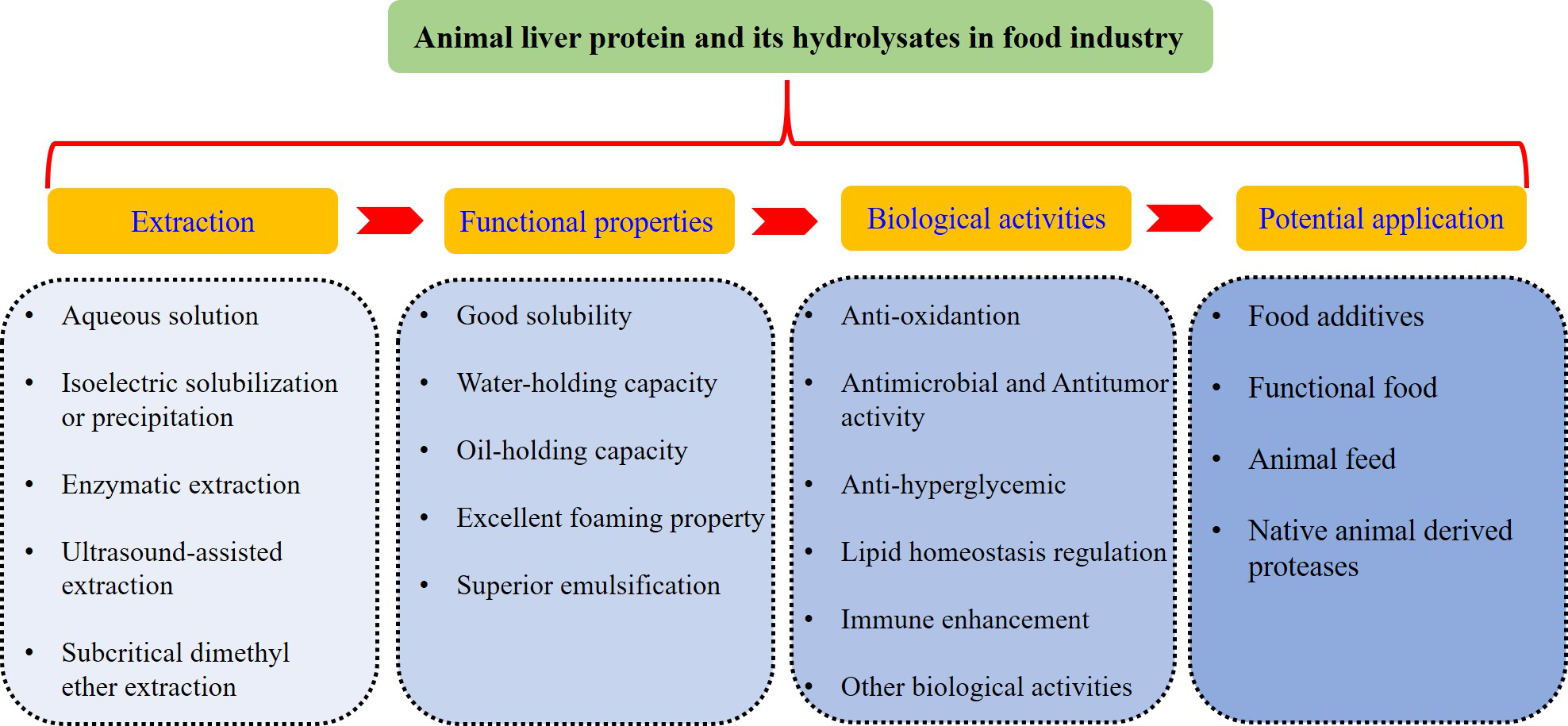

The aqueous salt solution and buffer systems are effective in solubilizing proteins and are most frequently used for their extraction. The use of dilute salt solution promotes proteins dissolution from natural plants and animal source. Ions from the salt combined partially with protein prevent protein denaturation in buffer solution (e.g., 0.02–0.05 M phosphate buffer) extraction. However, low extraction rate, large amount of solvent and complex extraction process of proteins are disadvantages that need to be overcome. Isoelectric solubilization/precipitation (ISP) adopts the principle that the lowest solubility of a protein is at its isoelectric point (IP), which is a safe and efficient extraction method for edible proteins. For protein from different sources, the pH gradient of ISP varies, so the final yield and properties of protein are different when using these extraction conditions. The use of acid-base reagents in ISP extraction leads to environmental concern, due to the use of chemicals, which is a disadvantage of using this method for industrial extraction of animal liver protein.

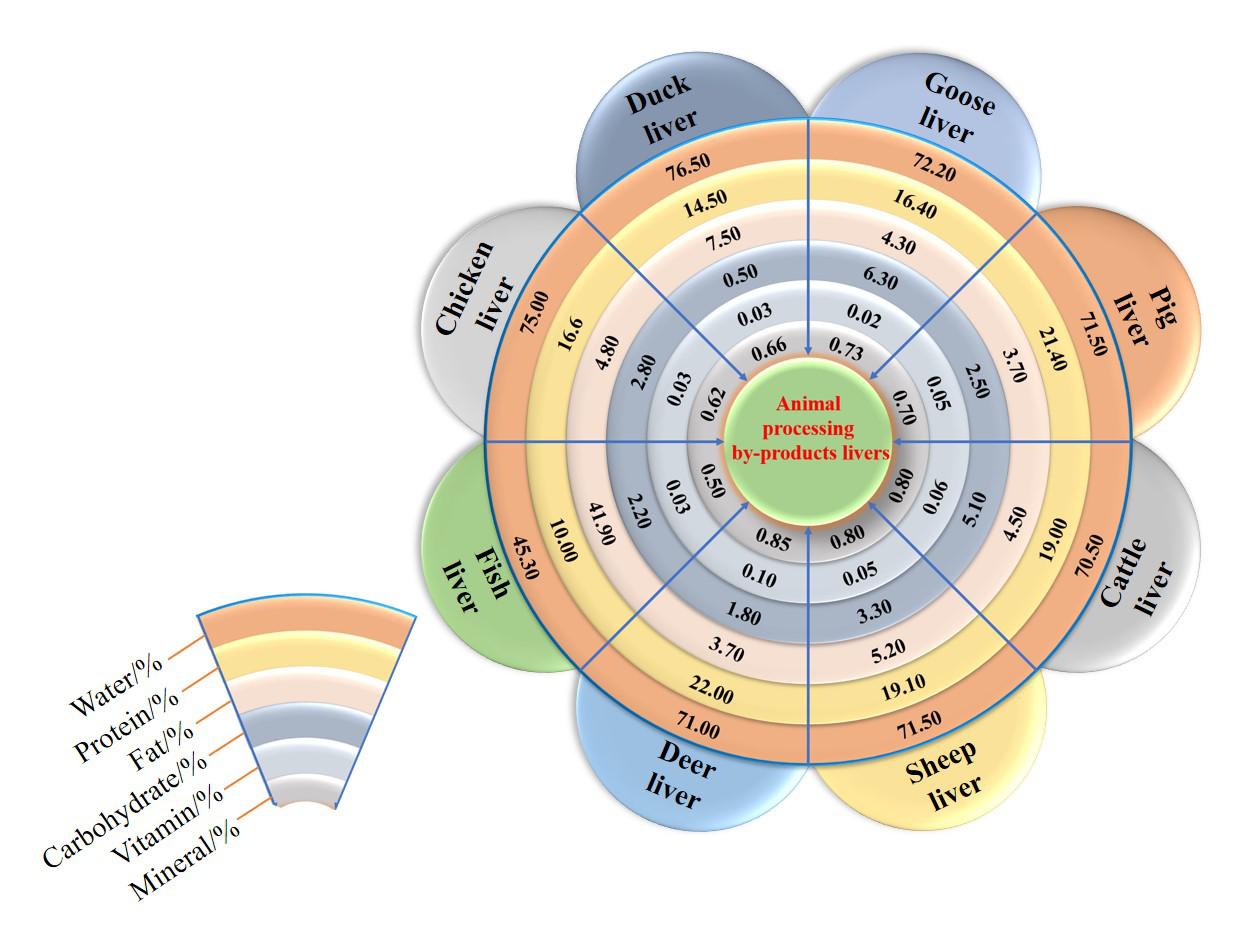

Fig. 1. Basic components (water, protein, fat, carbohydrate, vitamin and mineral) of liver from chicken, duck, goose, pig, cattle, sheep, deer and fish.

Animal liver protein and its hydrolysates have attracted much interest due to their broad applications in food, healthcare, animal feed and veterinary products. However, there is a need for intensive research on biological activity of liver protein and its hydrolysates in organism as well as on the regulation in animal by-products. Therefore, liver protein and its hydrolysates produced at industrial level would offer a value-added product for meat processing industry, and helps achieving resource sustainability. Enzymatic extraction (EE) breaks down the high-molecular-weight proteins into low-molecular-weight polypeptides and promotes protein release from raw materials. The selection of enzymes is important for EE as the high enzyme activity can be only obtained under the optimum temperature and pH. Additionally, antioxidant peptides from SLPHs were obtained using alkaline phosphatase, bromelain, flavourzyme and papain with different pH and temperature conditions. These investigations indicated significant value of animal livers for generating bioactive peptides. Ultrasound-assisted extraction (UAE) is regarded as a “green technology” to extract animal and plant protein because of its advantages of high efficiency, energy saving and environmentally friendly approach. In industrial production, round container tanks with large diameters are used to create ultrasound blank area, but this leads to the attenuation and loss of ultrasound energy. In addition to the aforementioned methods, other efficient extraction methods such as subcritical dimethyl ether extraction (SDEE) and sucrose density gradient centrifugation (SDGC) may be mentioned. SDEE could remove lipids and water simultaneously and conveniently so that the resultant protein content is relatively high (88.51%).

Fig. 2. Overview study of protein and its hydrolysates from animal livers.

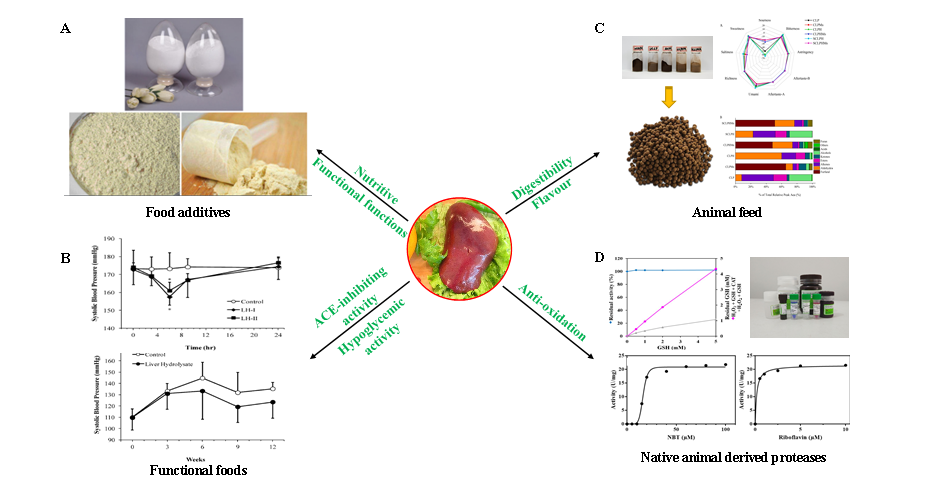

Liver protein and its hydrolysates do not only contain essential amino acids that strengthen the nutritional function of food, but also control the texture and taste of food. Liver protein has high foaming, fat absorption capacity, emulsifying activity and emulsion stability. With continuous improvement of people’s concept of environment, economy, health and low carbon footprint, animal by-product proteins as foaming and emulsifying agents will be widely advocated. Using different amounts of liver protein hydrolysates (LPH-1, LPH-2 and LPH-3) was found to decrease aerobic plate counts, yeast mold counts and coliforms with an increase in LPHs concentration. Due to its low drug resistance, high efficiency, low toxicity and broad-spectrum activity, research on antitumour bioactive peptides has become popular globally. With the intensive study on the antitumour effect and its mechanism of animal liver protein and peptides, it is expected that these products may well be used as efficient antitumour drugs in clinical applications. Liver hydrolysates (LHs) have the effect of lowering blood glucose in SHR/NDmcrcp (SHR-cp) rats that showed spontaneously occurring metabolic syndrome-like abnormalities. Consumption of LHs significantly inhibited hepatic activities of lipogenesis enzymes such as glucose-6-phosphate dehydrogenase and fatty acid synthase, thus it slightly increased fecal excretion of total fat. Therefore, SPLHs could significantly reduce the growth and the weight of fat pad including perirenal and epididymal adipose tissues in rats.

Fig. 3. Biological activities of animal liver protein and its hydrolysates. (A) Protective mechanisms of yak liver protein against proliferation and apoptosis of human hepatoma HepG2 cells. (B) Anti-hyperglycaemic mechanisms of peptide S-8300 in pancreas. (C) Protective mechanisms of chicken liver hydrolysates (CLHs) against high-fat dietary habit in three different organs. For small intestine, CLHs can inhibit lipase activity and improve bile-acid binding activity. For liver, bioactive compounds (amino acids and carnosine) exhibit a synergistic effect on lipid lowering and antioxidant status. For myocardium, high-fat diet habit causes the accumulation of autophagosome in myocardium, and CLHs can block autophagy pathway by lowering LC3II content. As a result, the reduction of autophagy accumulation can alleviate inflammation reaction and finally reduce cardiac fibrosis. (D) Icon illustration.

In order to develop the industry of liver protein and its hydrolysate products, it is necessary to pass relevant regulations for quality assurance aspects and safety issues to meet the needs of the international market. Therefore, with the improvement of processing technologies, legislation and potential safety hazard for animal livers, the preparation of animal liver protein and its hydrolysates is bound to become one of the most attractive emerging industries in future.

Fig. 4. Potential applications of animal liver protein and its hydrolysates. (A) Food additives. The liver protein powder or corresponding hydrolysates can be applied based on their excellent foaming and emulsifying properties. (B) Functional food. (C) Animal feed. The Maillard reaction products of liver manifest abundant volatile flavour substances according to the electronic tongue profile. (D) Native animal derived proteases. These proteases present good resistance against oxidative damage and efficient enzyme ability based on the descriptions provided by Chafik et al. (2017) and Chafik et al. (2019).