Separation membranes derived from block copolymers (BCPs) have attracted significant interest due to their well-defined pores and functional surfaces. However, it still remains a challenge to prepare ultrathin BCP composite membranes in an efficient way. Here we report a facile approach for the fabrication of ultrathin BCP composite membranes by forming thin films on water surface. The BCP layer as thin as ~ 17 nm can be prepared by spreading polystyrene-block-poly(2-vinyl pyridine) (PS-b-P2VP) solutions on water surface followed by controlled evaporation. The thin layer can be readily collected and composited with macroporous supports. A thickness of ~ 260 nm of the BCP layer is necessary to guarantee the integrity. Interconnected nanoporous structures are then obtained in the BCP layer by the process of selective swelling induced pore generation. On account of the ultrathin separation layer, the composite membranes exhibit excellent permselectivity, better than many other ultrafiltration membranes. Moreover, the separation performances can be facilely regulated by tuning the swelling durations. This method is featured as cost-effective and convenient, and is expected to provide a higher chance for the production of BCP membranes at large scale.

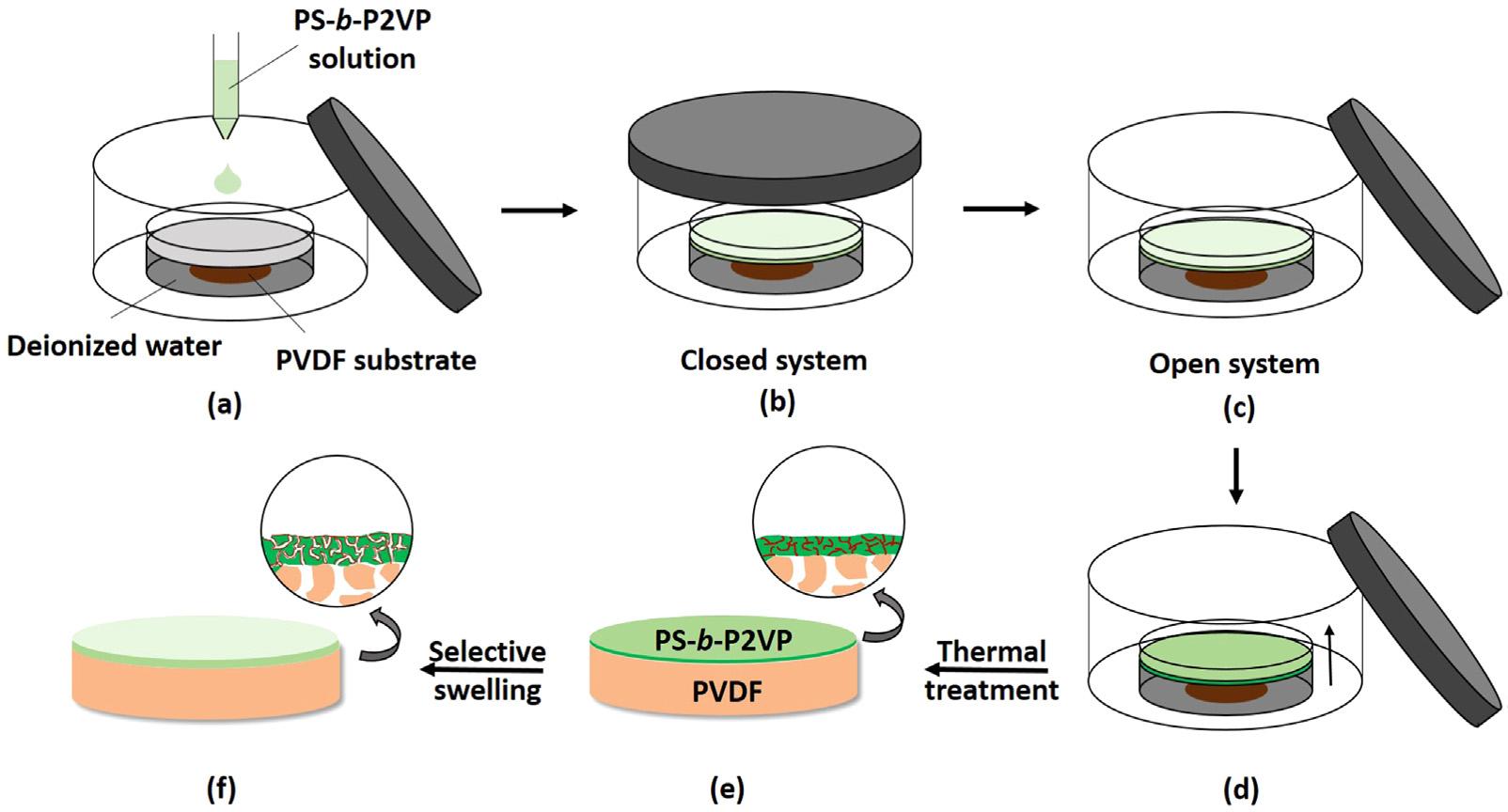

Fig. 1. The schematic diagram for the fabrication of PS-b-P2VP composite membranes on water surface. (a) Dosages of PS-b-P2VP solution added dropwise to the water filled in a weighing bottle with PVDF substrate preset at the bottom; (b) slower evaporation of the solvent in the container; (c) solvent evaporation in open air; (d) the as-formed PS-b-P2VP films collected directly by the preset substrates; (e) the composite membranes with PSb-P2VP layer atop PVDF substrate after thermal treatment and (f) the composites with mesopores cavitated in the PS-b-P2VP layer by selective swelling.