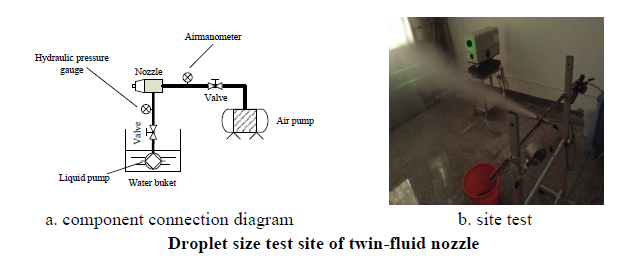

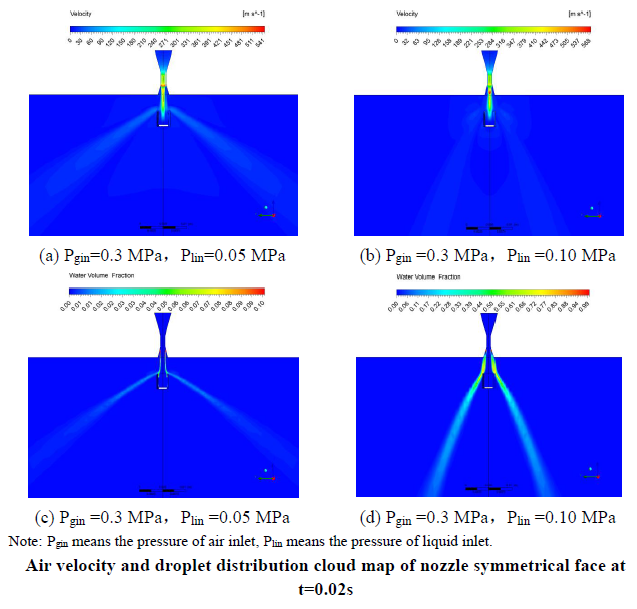

Diffusing spray can improve the adhesion of droplet on leaves and penetration on canopy compared with traditional chemical application in greenhouse production system. While the droplets of diffusing spray should be fine enough and with a certain initial velocity, which limit its development to some extent because of the lacking of specialized nozzle. As a result, an agricultural twin fluid nozzle is designed based on the Venturi principle. FLUENT and CFX were used to simulate the airflow field of the nozzle and the experimental verification was done as well. Results show that: The air velocity in the center area of the nozzle outlet could reach subsonic and supersonic velocity and with the increase of the two-phase pressure, the air velocity increased accordingly. When the air pressure was constant, the air flow would concentrate towards the axial direction with the increase of water pressure. The relative deviation of air velocity between measured and simulated values was ≤10%, indicating that the simulation results were reliable. Droplet particle size test results show that: With a constant water pressure of 0.05 MPa, the particle size range of the droplets decreased with the increase of the air pressure. Under the commonly used operation pressures (0.2 - 0.4 MPa) with the distance of 1.6m away from the nozzle, the ratio of droplets below 65 μm was ≥85%, and D50<50 μm. The twin fluid nozzle has an excellent atomization performance, can obtain droplets at fog-level, realizing the ultra-low-volume spray. It is suitable for diffused spray prevention of the entire greenhouse.