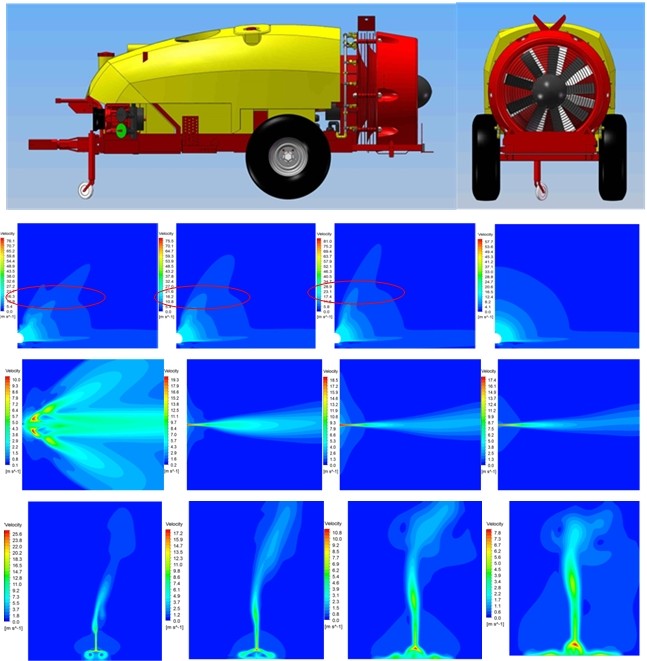

Under air-assisted spray conditions, droplets are carried by airflow through tree canopy and deposition, so the airflow distribution and movement is very important to droplet penetration and deposition. In order to research the 3D spatial distribution of airflow field from an air-assisted orchard sprayer, this article used ICEM to establish a geometric model, which whole structure was meshed, and was simulated by introducing k-ε turbulence model and CFX solver. The influence on airflow 3D distribution with different environmental systems for air-assisted orchard sprayer was estimated, through changing the airflow velocity (15ms-1,20 ms-1,25 ms-1 and 30 ms-1), upper deflector angle (30°、45°、60°、90°), and lower deflector angle (0°、10°、20°、30°). Results show that, to change the wind speed of the fan has no significant effect on airflow field distribution, merely increases airflow diffusion region. When the lower deflector angle increased from 0° to 30°, the decreases of ground friction resistance to the airflow, and the increases of the angle between resistances from ground friction and the air on both sides, that making one single air current to divide into 3 air currents gradually, so this kind of air distribution on horizontal plane has advantages on branches and leaves turning and droplets penetrating into fruit tree canopy. Airflow guided by deflectors mainly focused in the direction of deflector pointing, so the adjustment of deflector angle should be changed according to the height of canopy and tree trunk. The airflow velocity distribution in the vertical direction can be marched with the canopy shape curve, by setting suitable deflector angles, that could improve the effect of droplets deposition in canopy. The study found that the better effect of spraying in the general orchard, could be achieved by setting the upper and lower deflectors angle with 30°, and setting the upper deflector angle of 90° (or removed), lower deflector angle of 30° for spraying in trellised orchard. Such conclusions can be used to improve the calibration of operational parameters of sprayers for better spraying efficiency and reduced environmental impact.