The total mixed ration feeding technology has become the current large-scale cattle and sheep farm generally accepted feeding mode. Because it can be based on the nutritional needs of ruminant (cattle, sheep), refined coarse fodder, minerals, vitamins and a variety of trace elements in accordance with the appropriate proportion of the full mix, for the cattle and sheep to provide a stable proportion of fine coarse fodder, nutritional consistency of the complete ration of food. In the process of mutton sheep breeding in our province, we are faced with high labor intensity low level of automation, cannot meet the needs of modern aquaculture, and so on. This topic was to feed the sheep automation and mechanization, to establish suitable for the existing TMR mixer, design and manufacture suitable for the existing structure of sheep flock TMR automatic feeding machine, to enhance the modern management level of mutton breeding in our province. In order to ensure the production of mutton sheep in our province in the existing feed, drinking water and energy input capacity, through the implementation of the project to improve the production efficiency of sheep and the use of resources and energy efficiency.

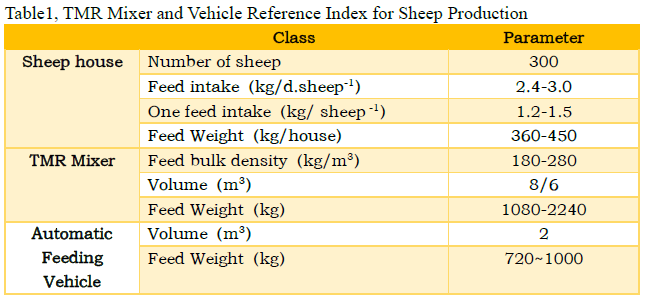

1. Determine the sheep farm breeding scale, feeding density, the proportion of feed intake and total mixed ration of single mutton sheep at different stages was designed to rationally design the volume and dynamic parameters of the TMR mixer, and the main structure of the sheep shed was investigated. Two kinds of main structure types, main construction parameters and management equipment were determined. The parameters such as size and power of TMR was designed, and parameters are provided for determining TMR feed intensive feeding technology;

2. The project determined the overall structure of the TMR automatic feeding machine and the TMR mixer, and determined the main design parameters. The design scheme of the automatic feeding machine and TMR mixer was proved, to establish the technical scheme of intensive feeding of large scale goat farm TMR feed. Aiming at the breeding scale of sheep farm and the structure of the Sheep house, the vertical mixer-conveyor belt type of the feeding machine, the bedroom mixer-the application scheme of stirring dragon type of Taizhou, and the applied research of the original ecological farm, the Taicang ecological farms and the Taizhou Helen Sheep Industry Co. The production of three automatic feeding machine and three TMR mixer and the demonstration of field application are completed, and the results are good.

Fig1, TMR Mixer

Fig2, Automatic Feeding Vehicle

3. The results show that the cement mixer and TMR mixer made sheep TMR feed density is higher to achieve bulk density respectively, (313±18.3) kg/m3, (283±6.1) kg/m3. At the same time, cement mixer production of TMR feed coefficient of variation is significantly greater than TMR mixer production of feed. Traditional cement mixer although the effect of mixing, because of higher water content of soybean residue. The top feed trough residue is at least about 1.6% of the total feed, the other is 13.8%, 22.7% and 61.9%, in order to increase. Cement Mixer Feed stratification ratio once for 7.6%, 24%, 18.4% and 50%. Both the bottom of the feed are more than 50% of the total feed, which is related to the use of grass powder sheep breeding. Water mixer only play a simple mixing effect of the second to third-storey station feed total of 42.4%, higher than the vertical mixer 36.5%.